Ihe na-eme ka mmiri gwụ mmiri

Ihe na-eme ka mmiri gwụ mmiri

- Teknụzụ na-eme ka ikuku mmiri na-ekpo ọkụ dị elu

Dị ka ígwè oxide - chromium oxide - potassium oxide nwere ike ime ka ethylbenzene (ma ọ bụ n-butene) dehydrogenation n'ime styrene (ma ọ bụ butadiene) n'okpuru okpomọkụ dị elu na nnukwu ikuku mmiri.

- teknụzụ catalytic dehydrogenation dị ala

N'ihi na mmiri na-ekpo ọkụ na-adịkarị mkpa ka a rụọ ya na okpomọkụ dị elu, nkwụsịtụ ma ọ bụ n'ihu ọnụ ọgụgụ dị ukwuu nke diluents, ike oriri dị ukwuu.N'ime afọ ndị na-adịbeghị anya, e mepụtala dehydrogenation oxidative na obere okpomọkụ.Dị ka polyethylene nwere bismuth - molybdenum metal oxide catalyst site oxidative dehydrogenation nke butadiene.

Ihe na-akpata Hydrogenationọ bụghị nanị na a na-eji usoro mmepụta ihe, ma a na-ejikwa ya mee ihe n'ọtụtụ ebe na nhazi nhazi nke akụrụngwa na ngwaahịa.Dabere na ọnọdụ hydrogenation dị iche iche, enwere ike kewaa ya ụzọ atọ:

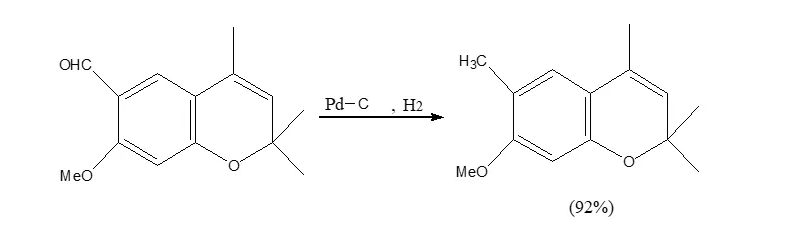

① Nhọrọ hydrogenation catalysts, dị ka ethylene na propylene enwetara site na petroleum hydrocarbon cracking dị ka polymerization akụrụngwa, ga-ebu ụzọ họrọ site hydrogenation, wepụ Chọpụta adịghị ọcha dị ka alkyne, diene, carbon monoxide, carbon dioxide, oxygen, na enweghị ọnwụ nke ene. .Ihe na-eme ka a na-ejikarị eme ihe bụ palladium, platinum ma ọ bụ nickel, cobalt, molybdenum, wdg, na alumina.

② Ihe na-akpata hydrogenation anaghị ahọpụta, ya bụ, ihe na-eme ka ikuku hydrogenation dị omimi banye ogige juru.Dị ka benzene hydrogenation ka cyclohexane na nickel-alumina catalyst, phenol hydrogenation ka cyclohexanol, nwere dinitrile hydrogenation ka hexdiamine na nickel catalyst.

③ Hydrogenation catalyst, dị ka ọla kọpa chromate catalyst maka mmanụ hydrogenation iji mepụta mmanya dị elu.

Ọ bụ ihe mgbagwoju anya izizi ejiri na mmepụta ụlọ ọrụ.A na-emepụta Aldehydes nwere otu carbon carbon ọzọ site na mmeghachi omume nke alkenes na syngas (CO + H2) n'ihu onye na-eme ihe.Dị ka ethylene, propylene dị ka akụrụngwa site na hydroformylation (ya bụ, nke a maara dị ka carbonyl synthesis) propyl aldehyde, butyl aldehyde.A na-eme hydroformylation n'oge mmiri mmiri na oke okpomọkụ na nrụgide site na iji carbonyl cobalt complexes dị ka ihe na-akpata.

A na-ekekarị polyethylene ka ọ bụrụ njupụta dị ala na njupụta dị elu.N'oge gara aga, nke mbụ na-eji usoro nrụgide dị elu (100 ~ 300MPa) mmepụta, oxygen, organic peroxide dị ka ihe na-akpata.A na-emepụta nke ikpeazụ site na usoro nrụgide ọkara ma ọ bụ usoro nrụgide dị ala.Na usoro nrụgide ọkara, chromium-molybdenum oxide na-ebu na silicon aluminum gluu dị ka ihe na-akpali akpali.Na usoro nrụgide dị ala, a na-eji ụdị ụdị Ziegler (nke titanium tetrachloride na usoro triethyl aluminum nọchitere anya) maka polymerization na obere okpomọkụ na obere nrụgide.Polypropylene mmepụta nwekwara ike akwado titanium-aluminom usoro nke elu arụmọrụ catalyst, kwa gram titanium nwere ike na-emepụta ihe karịrị 1000kg nke polypropylene.

Ọ bụ ihe mgbagwoju anya izizi ejiri na mmepụta ụlọ ọrụ.A na-emepụta Aldehydes nwere otu carbon carbon ọzọ site na mmeghachi omume nke alkenes na syngas (CO + H2) n'ihu onye na-eme ihe.Dị ka ethylene, propylene dị ka akụrụngwa site na hydroformylation (ya bụ, nke a maara dị ka carbonyl synthesis) propyl aldehyde, butyl aldehyde.A na-eme hydroformylation n'oge mmiri mmiri na oke okpomọkụ na nrụgide site na iji carbonyl cobalt complexes dị ka ihe na-akpata.

Dee ozi gị ebe a ziga anyị ya